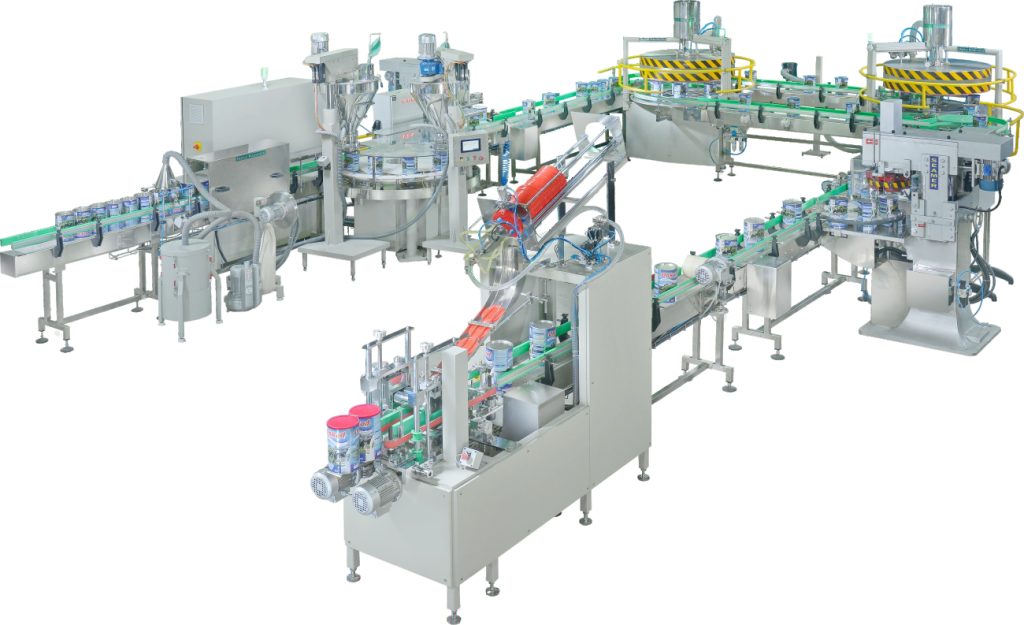

T Pack 2000D is a Complete Automatic Tin Packing Line comprising of Tin Cleaning, UV Sterilsation chamber, Tin Filling with load cell back up for accurate weighing, Automatic online Lid Clinching, Inline automatic Vacuumising and gas flushing units, online automatic final lid seamer and Tin capping unit. All the units are connected through transfer conveyor and are PLC controlled with HMI for operator convenience. Man and material safety features are incorporated in the design.

Change over one size to another size is possible with standard change parts, which extends the machine utility and enhance productivity.

TECHNICAL SPECIFICATION

| Output | 20 - 25 Tins / minute depending upon the product and pack size |

| Man Power | One Operator + 2 Skilled workers for loading Tin and Cap,etc., |

| Size Change Over | Possible |

| Power | 28 Kw, 440V, 50Hz, 3 Phase with Neutral and Double Earth |

| Compressed Air | 350 Ltrs / minute at 5 Kg / cm2 |

| Nitrogen 99.9 percentage purity | 30NM3/ HR at 6Kg/cm2 |

| Packing Line Layout | Straight, “L”, “U” Line layouts are possible to suite the customers packing hall dimensions |

Optional Attachments

- Screw conveyor with Hopper for material feeding

- Plastic cap applicator attachment

Reach Out to us for Machines Videos