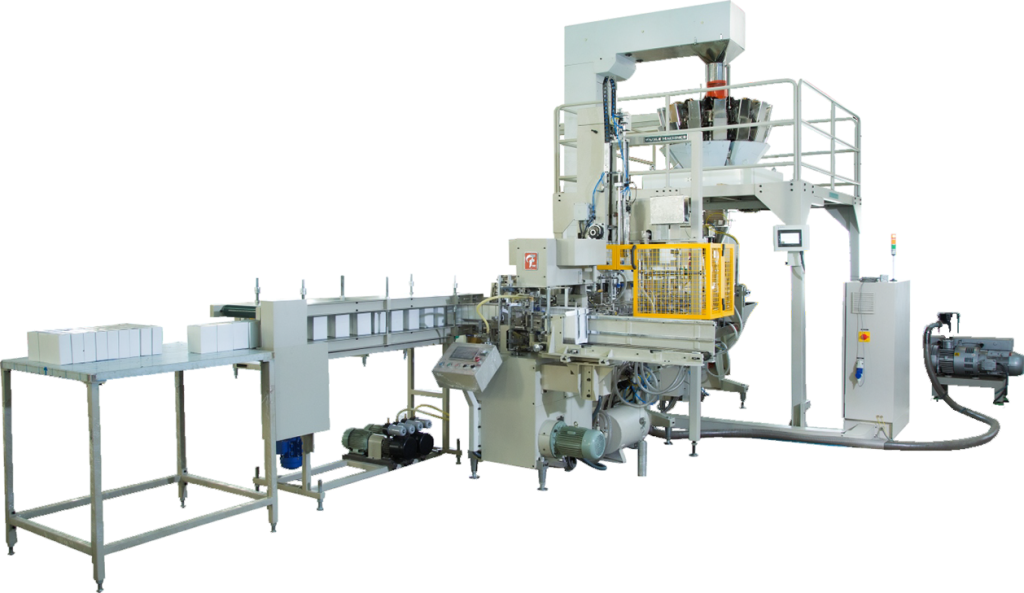

C Pack 3000BB is a intermittent vertical carton-er. In the carton magazine the cartons are loaded and every cycle one carton is picked up, erected in the holders provided and move to the next station. In this station bottom small flaps are folded and at the next station where the formed pre-made bag is inserted in to the carton.

The pre made bags stacked in a magazine, just above the carton carrier, are taken one by one in every cycle by vacuum arm which moves in synchronization with the carton erected at the bottom. The bags are opened and inserted in to the erected carton in the holder underneath thus forming the bag in box. The carton with the formed bag is moved to different stations where bottom flaps are glued, product filled, packet jogged to settle the product, rammed for product compact, top sealed, top flap glued and folded and the packet is rejected out to the pressure conveyor for the glue to set and the packets come out ready to be put in to shipping box .

TECHNICAL SPECIFICATION

| Output | Upto 30 packets / minute depending upon product and pack size . |

| Man Power | One Operator |

| Size Change Over | Possible |

| Pack Size : | |

| Carton Dimensions - mm | Min Max |

| Length | 80 150 |

| Width | 45 100 |

| Height | 100 230 |

| Machine Dimension | L 8 mtr X B 6.5 mtr X H 4.25 mtr |

| Electric Power | 18Kw, 440V / 50 Hz / 3 Phase with neutral and double earth |

| Compressed Air (Dry) | 350 Ltrs / Minute at 6 Kg/cm2 |

Attachment

- Multi head weigher with Mounting Frame

- Take out pressure conveyor for cold glue setting

Optional

- Bucket Elevator with Vibratory feeder